Everything starts with a hello. When you contact us at System Hall, we assess your needs and tailor a solution for you. From the first meeting to installation, we ensure the highest quality and performance. We are with you every step of the way and always available even after the machines are in operation.

This is what we do

We offer

Since our inception in 1986, we have built a solid portfolio of various automation solutions for the wood processing industry. We have always remained neutral regarding the machines you want to automate in your workflow, which has given us a unique position in the market as an automation provider. Below is a selection of the different types of automation we can help you automate and streamline.

Aftermarket services

Production/Machine/Collaboration

Industrial solutions are aimed at those needing a fresh start in daily operations and seeking continuous reports on areas for improvement. We assist in optimizing your production and creating a sustainable future.

Mechanical Assessment

This offer is for those who want to prevent mechanical downtime and expensive express deliveries. We assess the facility, evaluate production times, and ensure smooth operations.

Optimization

This service allows our staff to identify and implement production-enhancing measures. We optimize the line during operation for increased productivity and improved performance.

Webshop

We have an extensive inventory of critical spare parts for your production. Most of our stock is available in our webshop, helping you minimize downtime and maintain high production levels.

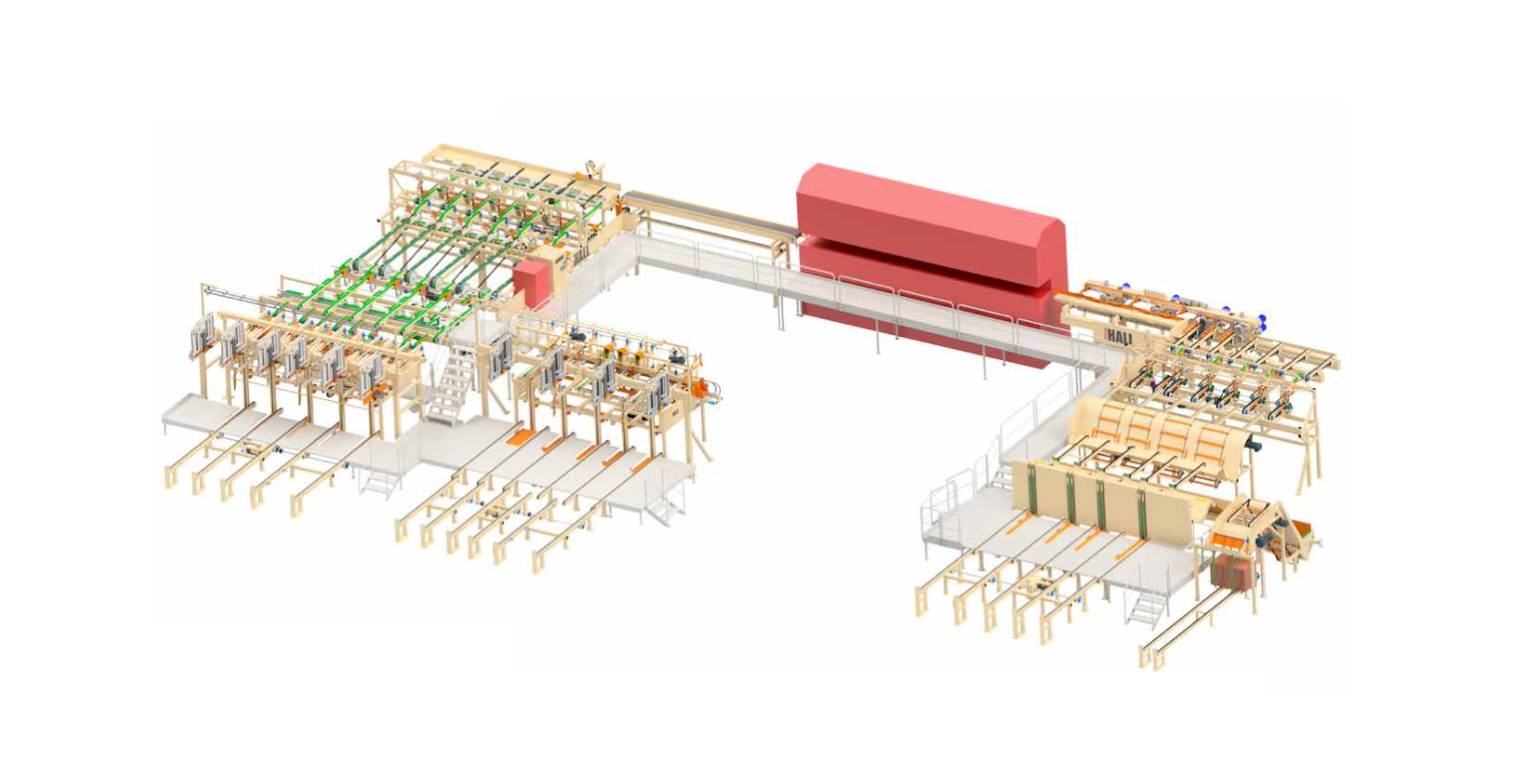

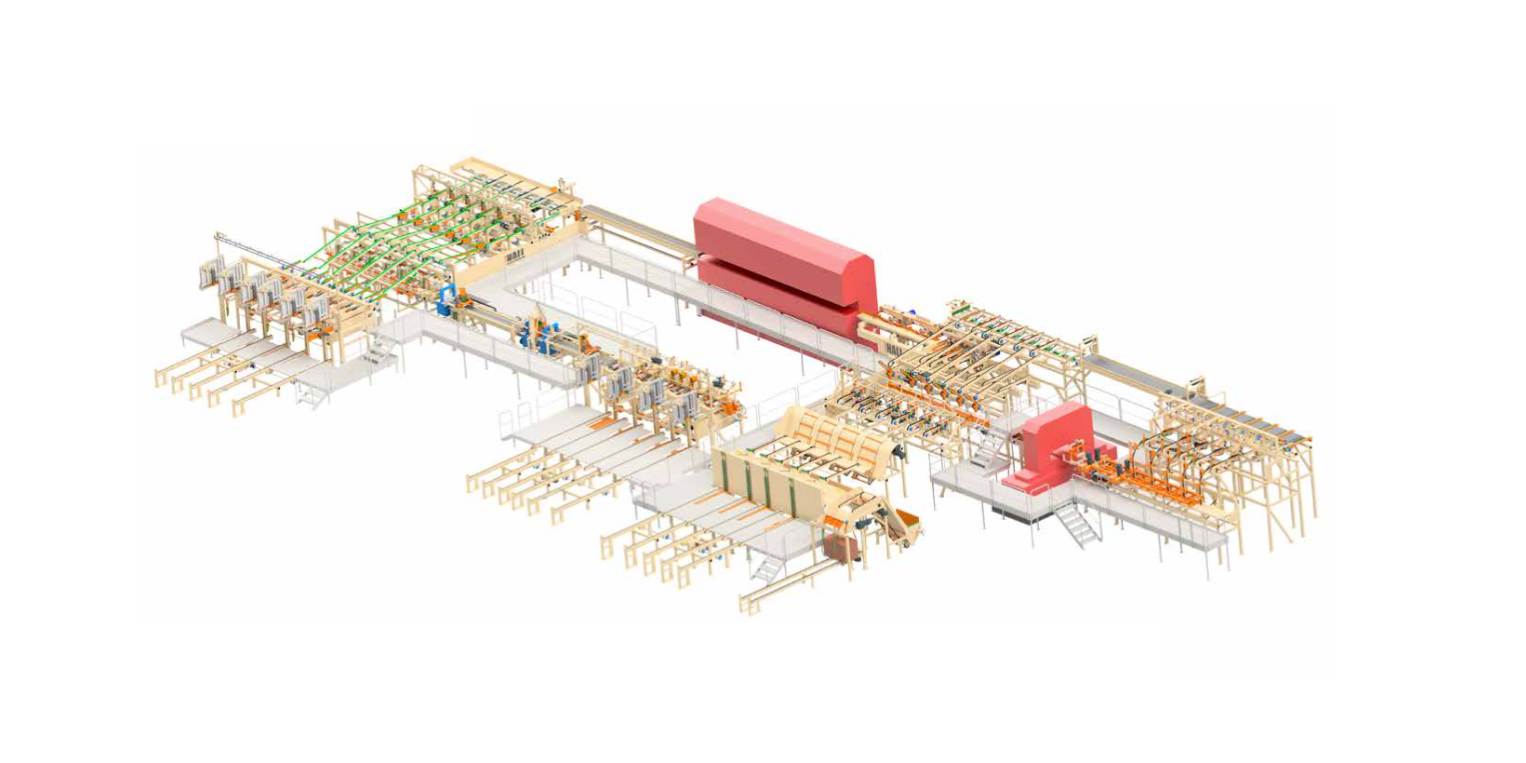

Concept lines

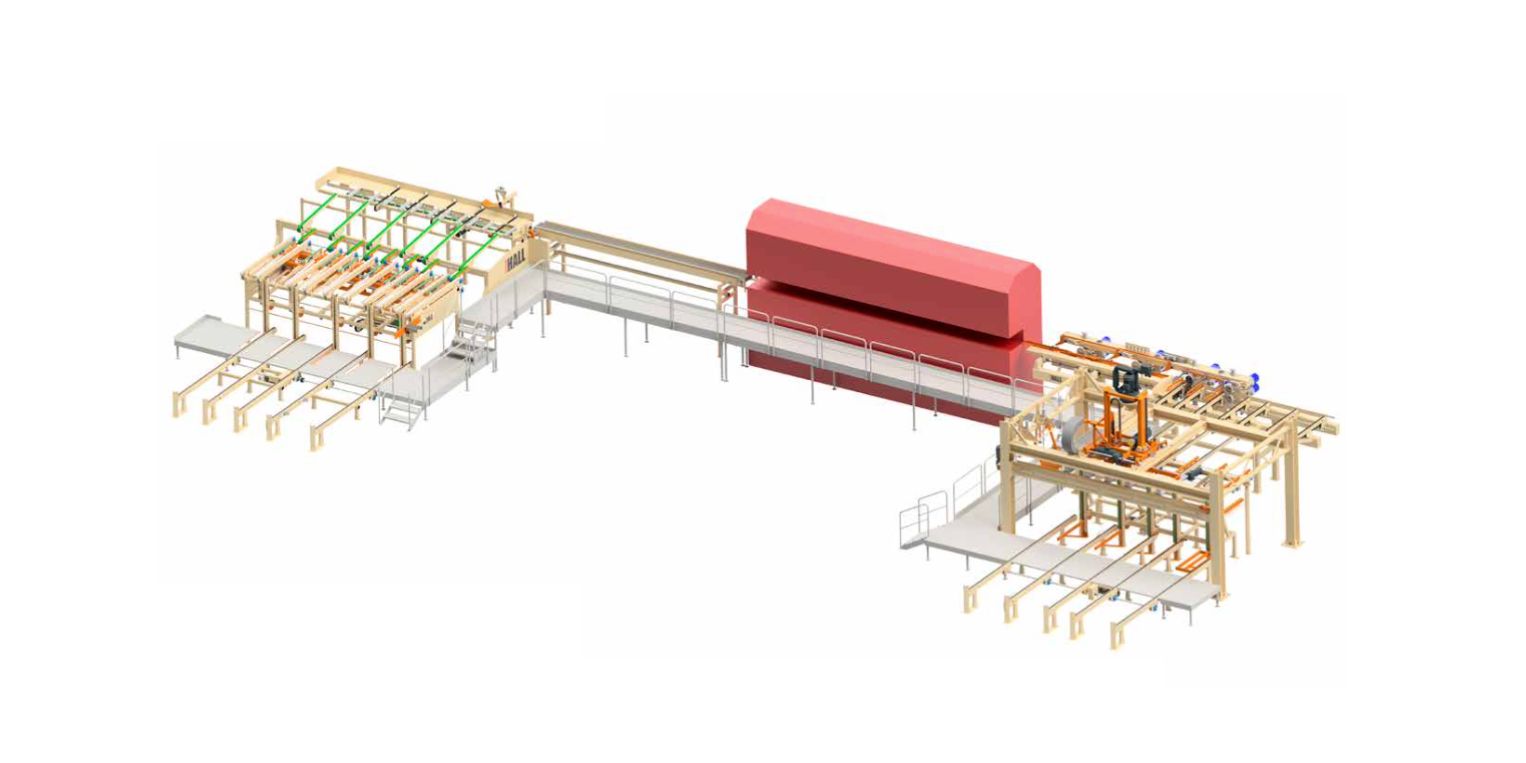

Line for construction 250

LFC250 is designed for fast and reliable processing of structural timber, with low downtime and easy maintenance. Control via touch panels allows for smooth adjustment of time and speed. Optional features include material sorting and ink marking. The line can also be used for four-sided planing, such as decking.

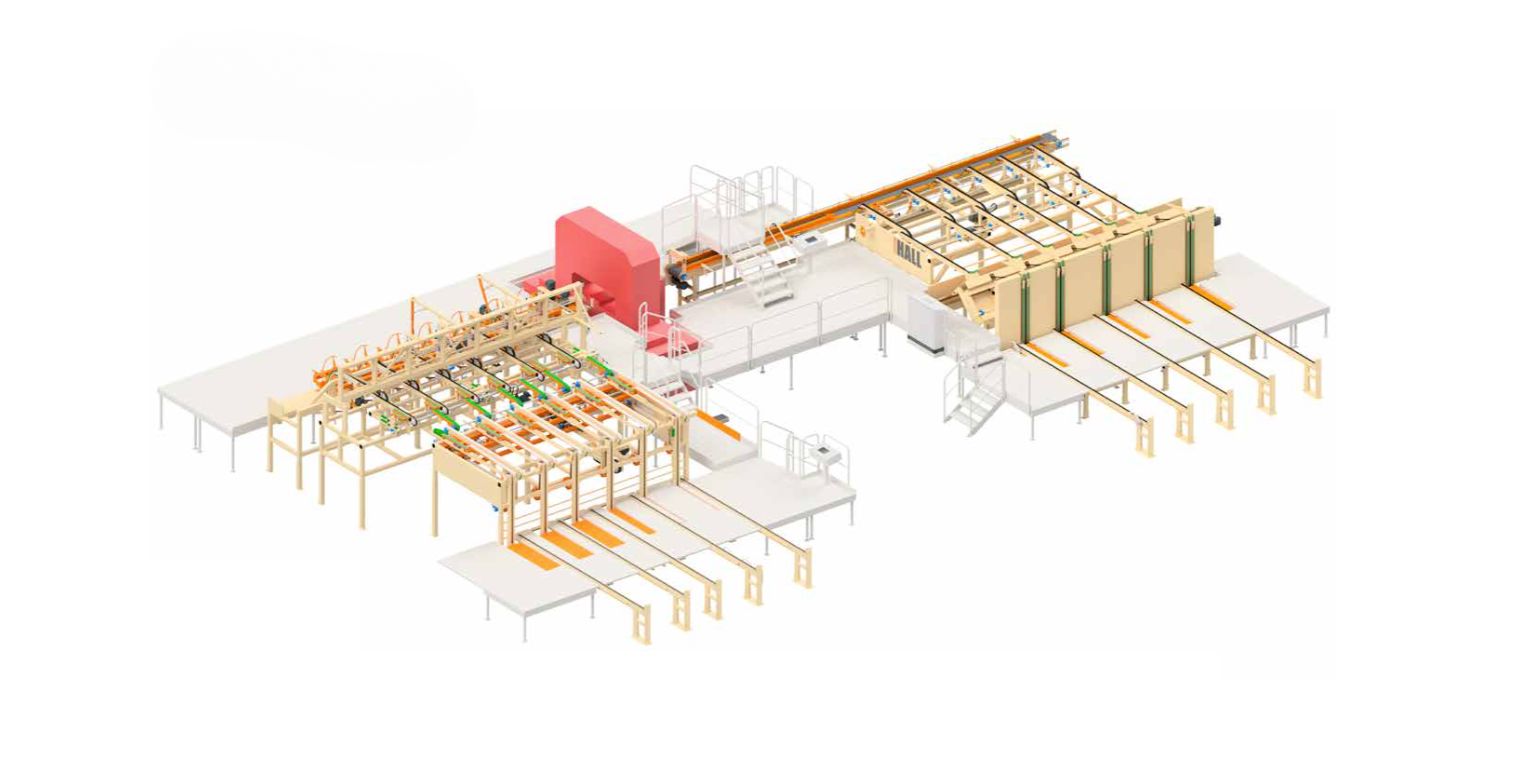

Panel line 250

LFP250 is designed for bundling and particularly suitable for panels, but can also handle battens and structural timber. The line is controlled via touch panels for easy adjustment of time and speed. The bundling unit is continuously upgraded with the latest technology, now featuring options to switch from pneumatic to servo motors. Reliable units such as tipping, lifting, and stacking are included, and all spare parts are available from System Hall.

Small planing line 150

SML150 is designed for businesses with smaller batches and custom orders. The equipment is easily adjusted via operator panels with storable recipes. The line is easy to learn and suitable for frequent operator changes. Optional stick dispensers and sorting options are available. The stacker has adjustable ends and variable speed motors. The vacuum lift handles all dimensions and includes stick removal. The line has few wearing parts and achieves 150 meters per minute with a pair of rollers.

Small bandsaw line 60

SBL60 is designed for flexible production companies with the possibility of single-operator operation and quick manual adjustments. The combined unit with tiltable bandsaw efficiently cuts various profiles. The units are renowned for their reliability and easy maintenance, developed over decades. All spare parts are readily available from System Hall HQ. SBL60 is highly space-saving, requiring only 21 x 13 meters, making it suitable for placement even in small premises.